Design programs

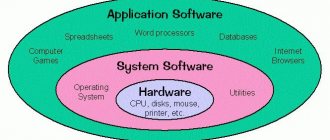

Nowadays, there is a huge selection of programs on the design software market. Initially, the market was captured by foreign software manufacturers. The programs were in English, all educational materials and manuals were also in English. Gradually, Russification programs began to appear, textbooks were translated into Russian. Afterwards, domestic programs began to appear on the market, and foreign manufacturers began to produce Russian-language versions of their programs.

Let's try to understand this variety of software for designers. For convenience, we will divide all programs into the following groups.

Cost of designing metal structures

You can order metal structures not only if you have a ready-made KM section on hand (in this case, production will require drawing up part of the KMD), but also from scratch - if you have the original documentation. Design costs vary depending on several factors:

- scope of work;

- project complexity;

- deadlines for completing the task;

- special requirements for the preparation of documents and drawings;

- completeness of the technical specifications;

- availability of preliminary sketches;

- the need to adjust the problem during the design process.

All articles

Programs for drawing.

| Go to section |

Drawing programs appeared, perhaps, first and were widely in demand both in Russia and abroad. One of the first such programs was AutoCAD. The principle of their operation was quite similar to ordinary drawing, with the only difference being that the lines were drawn not on paper, but on the screen. After completing the drawing on the screen, it could be printed on a printer. The main advantage is the ability to copy a drawing or its fragments for new projects. The quality of the drawings printed on a printer was incomparably better than drawings made by hand in pencil.

Programs for 3D development.

| Go to section |

Programs for 3D design as soon as computer capabilities began to allow rendering. The first were programs such as 3D MAX, etc. They immediately found wide application among architects and designers. Professional programs made it possible to obtain a very realistic image. Then the ability to work with three-dimensional graphics began to appear in programs that were originally intended for developing drawings, for example, programs such as AutoCAD and KOMPAS. The capabilities of constructing three-dimensional images were constantly increasing, and the set of tools for working with three-dimensional graphics was expanding. The graphics quality of these programs has reached a professional level, and the capabilities of these programs are successfully used to obtain realistic three-dimensional images.

CALCULATION PROGRAM LOGIKAL

LogiKal® is a multi-system calculation software package for façade and window companies from ORGADATA (www.orgadata.com), built on a modular basis. Provides a full cycle of business in the field of translucent structures.

LogiKal® is an easy-to-use program whose configuration, functionality and menu design are precisely tailored to the general needs of windows, doors and façades.

LogiKal® thinks with you. She constantly monitors the correctness of data entry so that possible errors do not appear.

The text editing interface allows you to use the integrated text editor of the LogiKal® program, Microsoft Office or other office solutions for reports.

Main features and capabilities:

- Step-by-step design of structures and preparation of documentation (KM, KMD)

- Cost calculation and preparation of commercial proposals

- Calculation and preparation of documents for material purchases

- Generating sections for products

- Working with different databases.

LogiKal guides the user through the entire process safely and efficiently.

The first step in LogiKal is to enter elements. An advanced logic-controlled process during input ensures that only the correct components and solutions are proposed at the appropriate stage.

Calculations. LogiKal automatically determines the appropriate costs for all elements. Purchase prices are considered by the program based on optimization of cutting and labor hours and are formed based on the selected design and components, etc.

Construction. A wide range of rules and regulations are integrated into the program, which makes it possible to enter data from the client quickly and, at the same time, safely.

Changes. If the dimensions of an object require adjustment, then all changes made are instantly linked to the change history tracking function.

Preliminary calculation of statics. Based on regional conditions and installation area, LogiKal will determine the impact of loads and ensure the optimal size of each component from an economic point of view.

Optimal quantitative calculation. LogiKal automatically quantifies the material for the order. Material cutting is optimized based on the lengths of profiles, calculation of components in multiples of packaging, sheets and panels based on existing formats

Construction in CAD. LogiKal CAD offers a complete CAD system with extensive design tools. LogiKal provides a robust interface that allows you to quickly access CAD programs directly from LogiKal.

Production planning. LogiKal automatically generates an extensive list of documentation and production drawings for production. No additional hardware programming is required.

Control of CNC equipment. LogiKal provides support for virtually all double-head CNC miter saws and machining centers currently available on the market for the production of aluminum and PVC products.

Programs for developing KM and KMD drawings

| Go to section |

Specialized programs for developing working documentation for metal structures did not appear by chance. The specificity of this documentation is such that when developing drawings, the designer spends a lot of time performing such primitive operations as drawing simple individual parts, calculating specifications, etc. The construction of the three-dimensional model of the metal frame itself takes a relatively short amount of time. The ultimate goal of such programs was initially simple and specific: the engineer makes a three-dimensional model, and the program automatically generates a set of ready-to-use drawings. But the path to this goal for many programs was long. The first versions were very far from this goal. The drawings required a lot of revision. Currently, some programs, when properly configured, allow you to obtain drawings with a very high percentage of completion. The time spent developing drawings in such specialized programs can be ten times less than in conventional drawing programs using two-dimensional drawing.

Development of drawings

The documentation required for the construction of metal structures includes two sections:

- Architectural solution - a description of the appearance and internal structure of the assignment, containing a sketch of the facade indicating the color of the finish, a floor plan of the building, an explication, and a list of materials necessary for the presentation of the object.

- Design solution - a detailed description, justification and purpose of all individual elements that determine the strength and durability of the object. Documents included: drawings of the main sections of the building indicating the nodes and load-bearing supports, markers of the position of floors, ceilings and beams, load calculation plan, foundation sections, description of the roof geometry.

Photo No. 1: development of technical documentation

No construction is complete without a work project that describes the selected engineering solutions, ways to eliminate possible problems at the construction site, a list of the mechanisms used and other necessary information. If the contractor does not provide this certified document, the customer may not allow the work to begin. Using a work plan can significantly reduce construction time and minimize costs. In addition, the presence of a certified document is the key to speedy approval of construction with regulatory organizations.

The next step is to create a design project. To convert the graphic part into a calculation model, special software is required. The software for designing metal structures takes into account the significance of loads (snow and wind) taking into account the climate in the region, as well as the weight of the equipment and its impact on the supporting foundations. The data obtained becomes the basis for determining the cross-section and strength properties of load-bearing elements, taking into account the required safety factor for connections.

3D design of metal structures is carried out in the following programs:

- Tekla Structures;

- Advance Steel;

- AutoCAD;

- Compass 3D;

- Bocad-3D;

- CAD-PLAN ATHENA 2006.

Photo No. 2: 3d design of metal structures

Programs for developing design drawings

| Go to section |

Programs for the development of working documentation for reinforced concrete structures appeared almost simultaneously with programs for the development of KM and KMD drawings. Essentially the task is the same: Based on a three-dimensional model, obtain a ready-made package of working documentation. The difference between these programs lies in the design features of the three-dimensional model and the structure of the final working documentation. Taking into account the modern requirements of regulatory documents, it is not easy to obtain design drawings automatically. But eventually this problem will be solved.

Approximate cost and terms

The cost of the project is always calculated individually according to the requirements of each individual customer.

The cost of manufacturing a metal structures project cannot be tied to tonnage .

On average , if we are talking about working documentation for the KM and KMD sections , for example, for a standard store building with an area of 150 sq. m. - the cost will be around 60 - 120 thousand rubles.

The cost of a project for examination is several times more expensive than the working documentation for construction. Read more in the “Building Design” section.

You can order the design of metal structures and clarify the cost of services by contacting the company’s managers by phone +7 (495) 118-36-14 or write to [email protected] .

| Name of metal structures | Price |

| Frames of buildings and structures made of metal structures | from 80,000 rub. T. |

| Bridge metal structures and pedestrian crossings | from 102,000 rub. T. |

| Facade metal structures, half-timbered structures | from 82,000 rub. T. |

| Columns with different sections and parameters | from 82800 rub. T. |

| Farms | from 81800 rub. T. |

| Welded beam | from 81800 rub. T. |

| Crane beam, floor beams | from 84800 rub. T. |

| Metal structures of overpasses | from 84800 rub. T. |

| Pipeline supports | from 84800 rub. T. |

| Cable structures | from 83800 rub. T. |

| Stairs, stringers, fences | from 92800 rub. T. |

| High-rise structures, masts, portals | from 92800 rub. T. |

| Tanks and reservoirs | from 96800 rub. T. |

| Metal canopies | from 84800 rub. T. |

| Anchor groups | from 92,000 rub. T. |

| Embedded parts | from 75,000 rub. T. |

We will install metal structures from RUB 25,000. per ton. More details in this section.

Programs for structural calculations

| Go to section |

The use of computers for calculations of building structures began with their appearance. Perhaps this is the first thing that computers learned to do. This happened back in Soviet times with the advent of the first computers. (Electronic computers). Nowadays, these programs have spread to such an extent that many design engineers have long forgotten how to perform these calculations manually. It is enough to enter the initial data and the computer produces a certified calculation result.

BIM design software

| Go to section |

The concept of design using BIM technology appeared relatively recently, and is now being actively implemented with strong government support. The essence of the technology is that the model contains complete information about the building, starting with preparatory work, structures, communications and ending with the period of maintenance and operation of the facility. Some people criticize this technology, others praise it. And the reason is very simple: the larger the object, the more appropriate it is to use BIM technology. If you design stalls, small shops, private cottages, then the use of this technology will not bring much benefit and the smaller the object, the more pointless it is to use this technology. And vice versa, the larger the object, the greater the effect the use of this BIM technology will bring, especially during the construction of large unique buildings and structures with a long construction and operation period.